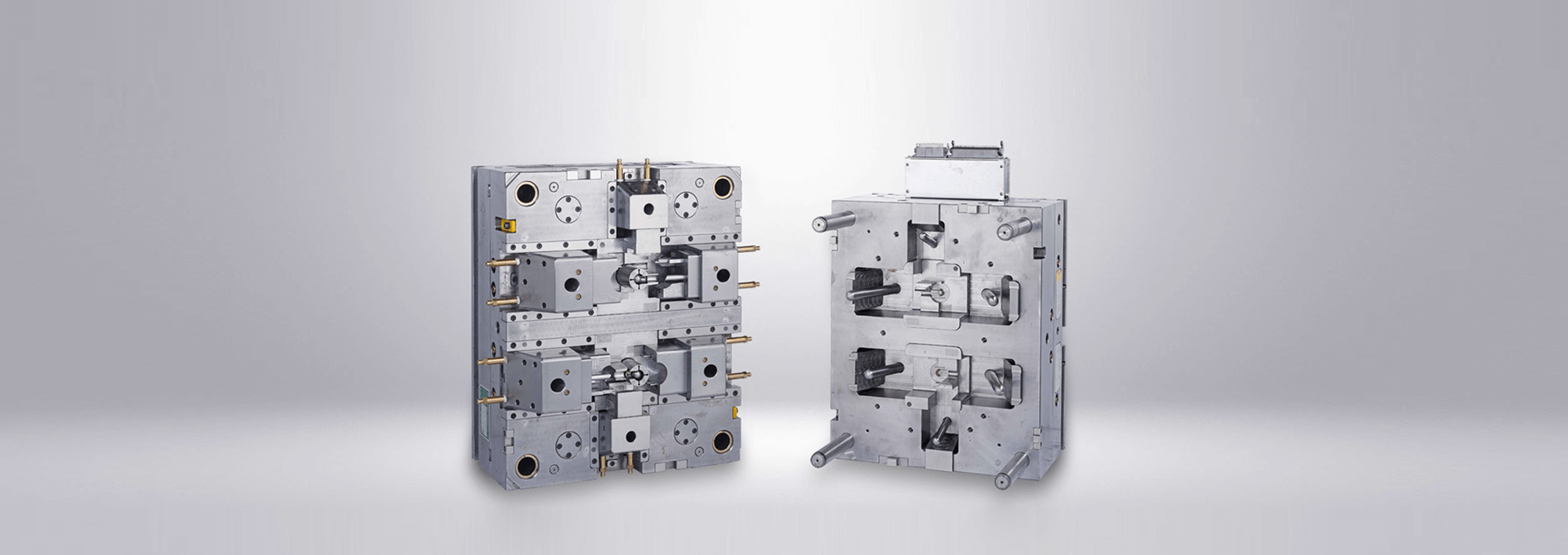

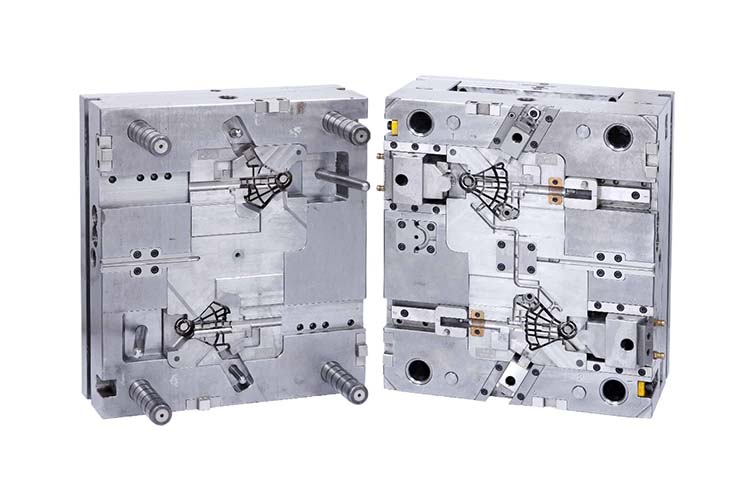

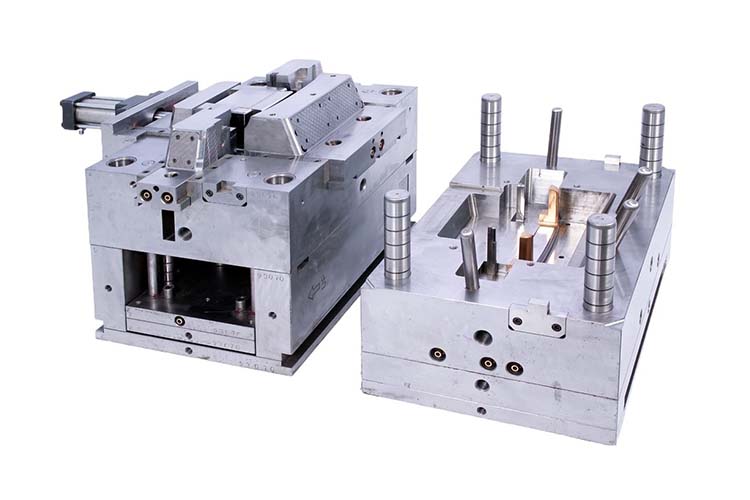

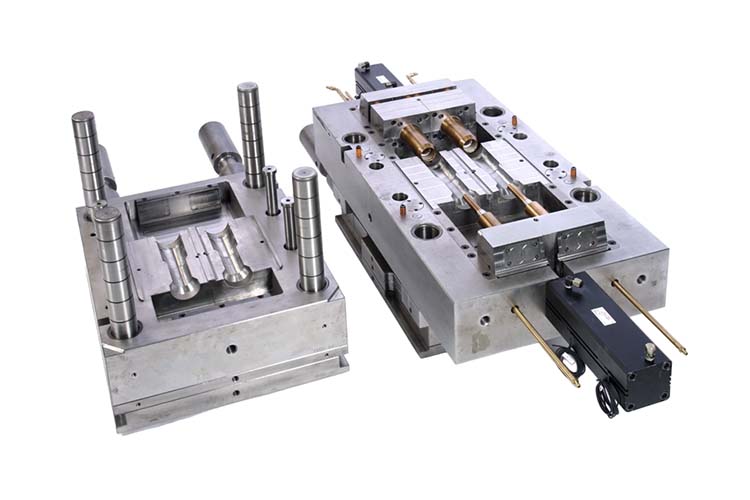

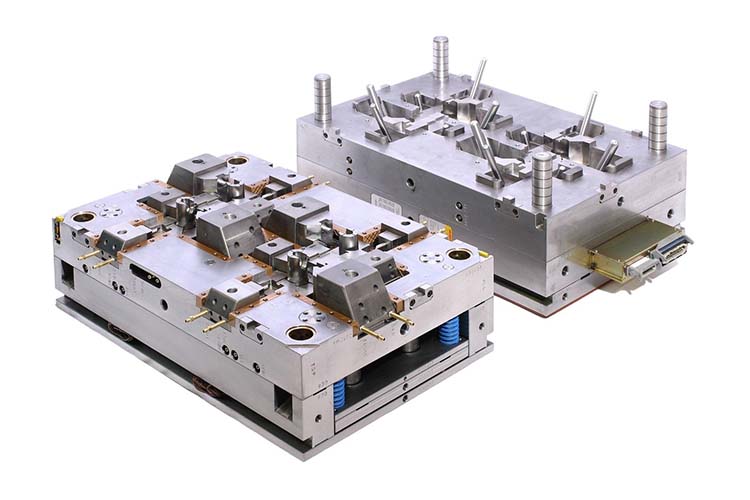

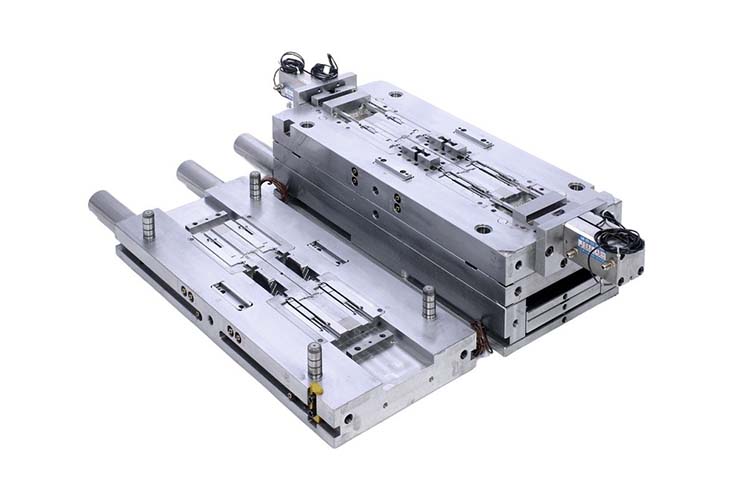

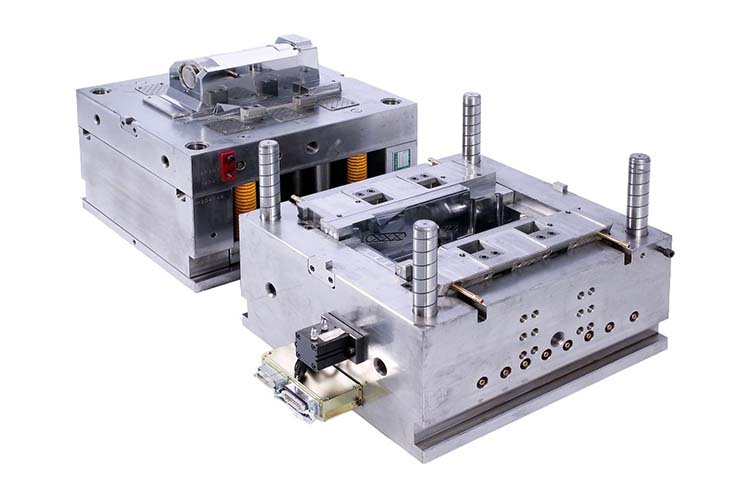

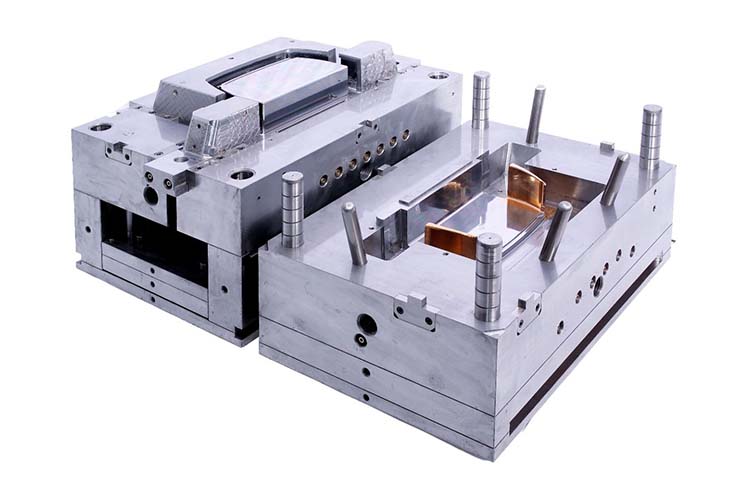

Plastic Injection Mold

We could make a various range of plastic injection mold for all over the world. Including appliance product, fitness components, automotive parts and various electric/electronic parts in different system like DME, Hasco and so on. With good communication with customers we did a lot of good jobs for our customers.

Catalogue