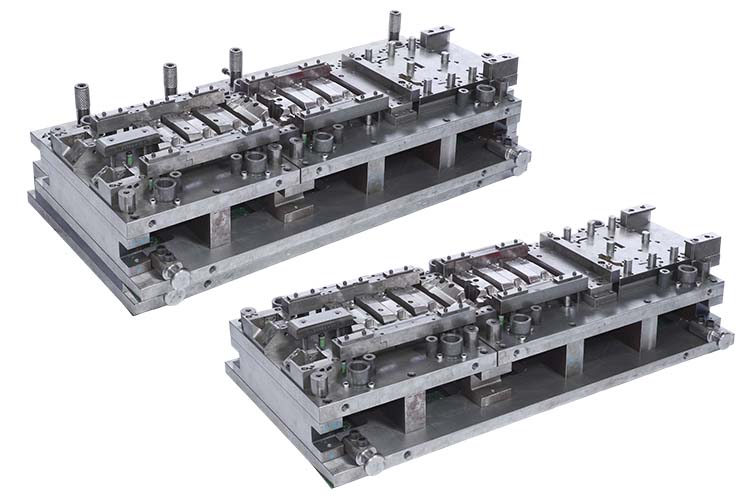

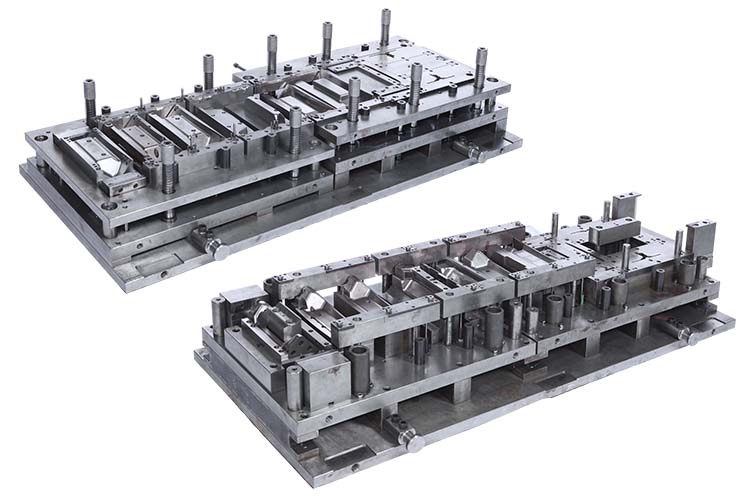

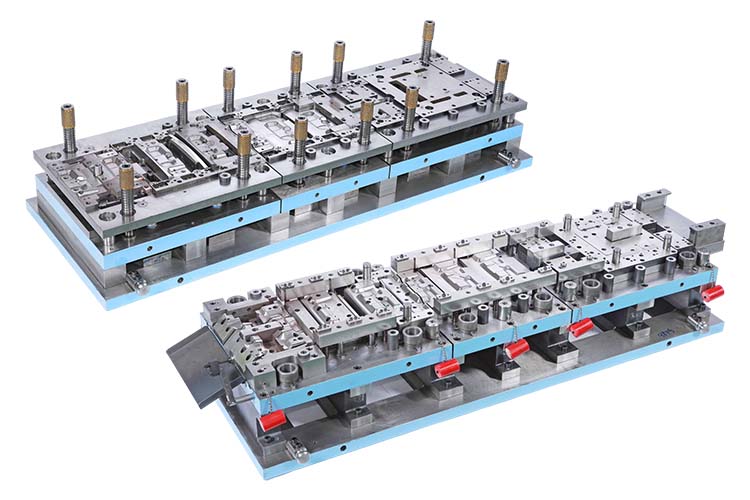

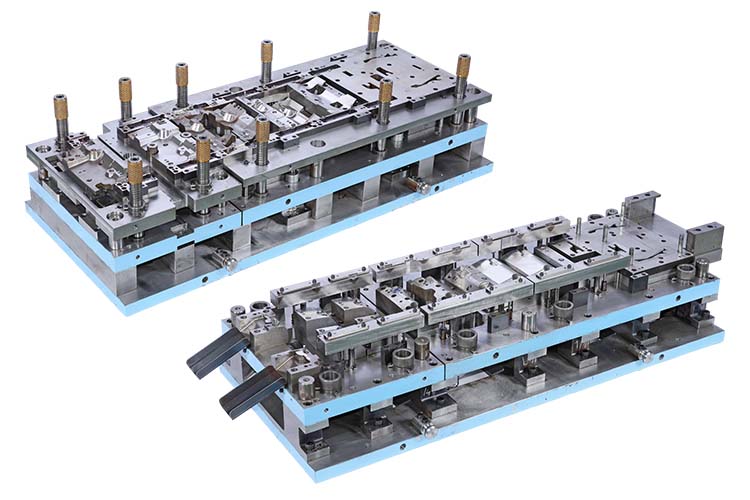

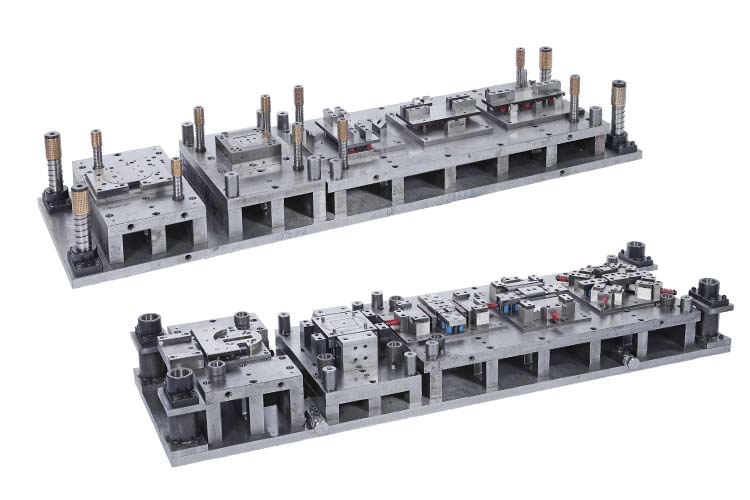

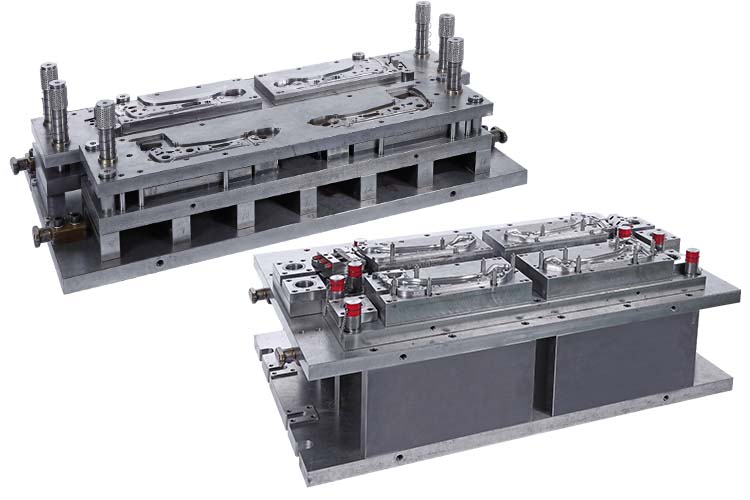

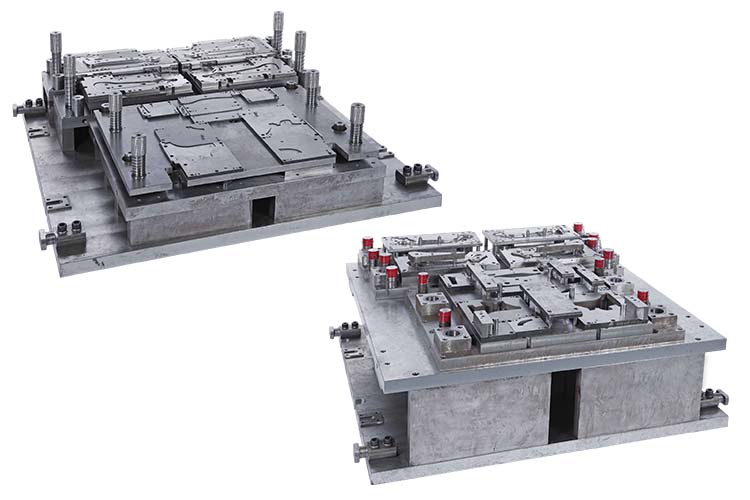

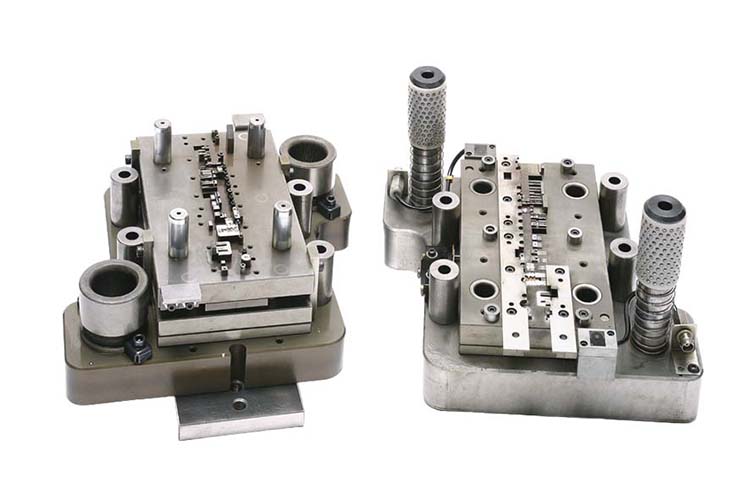

Metal Stamping Die

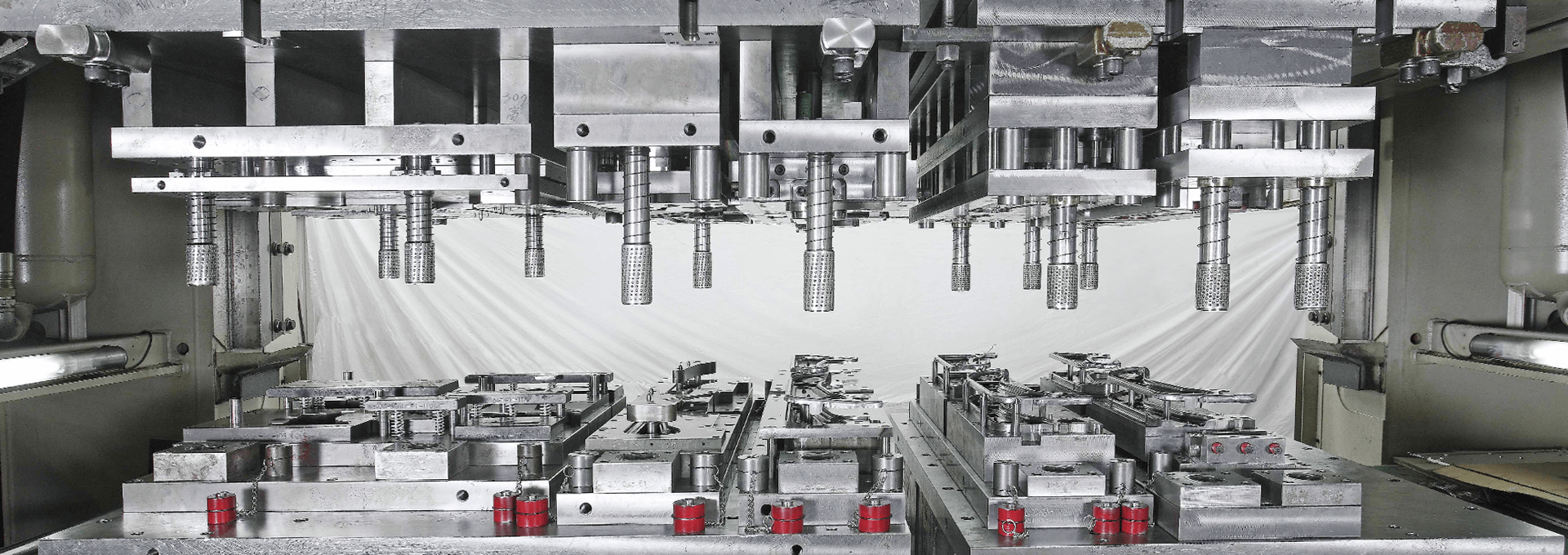

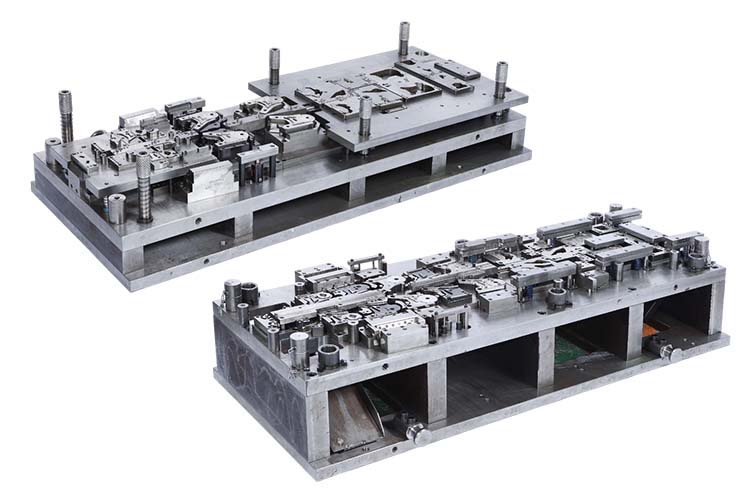

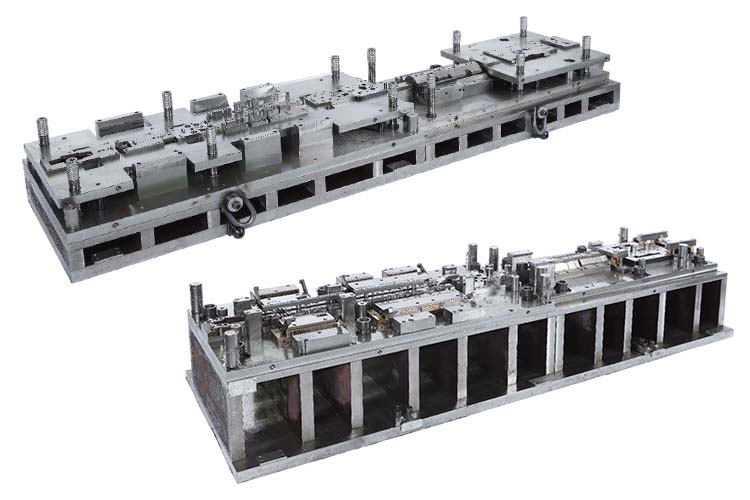

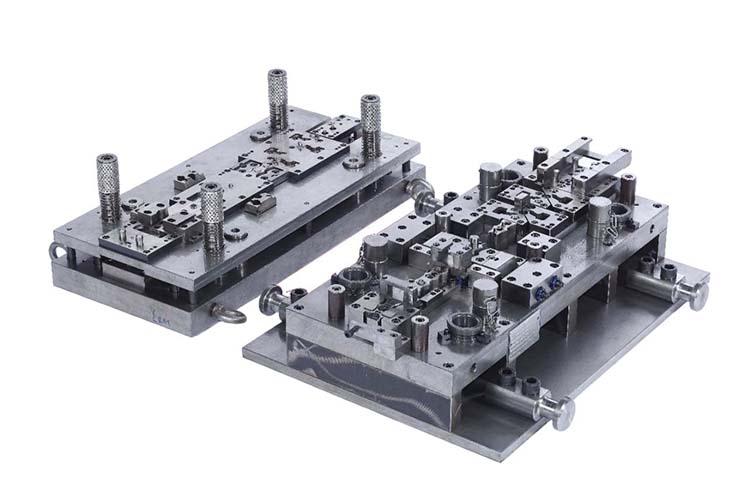

Race Mold designs & manufactures metal stamping tools.

Our experience includes work in the automotive, motorbike, ATV, lawn & garden, cookware & appliance industries.

We specialize in progressive & automated transfer dies & stock thickness to 5mm.