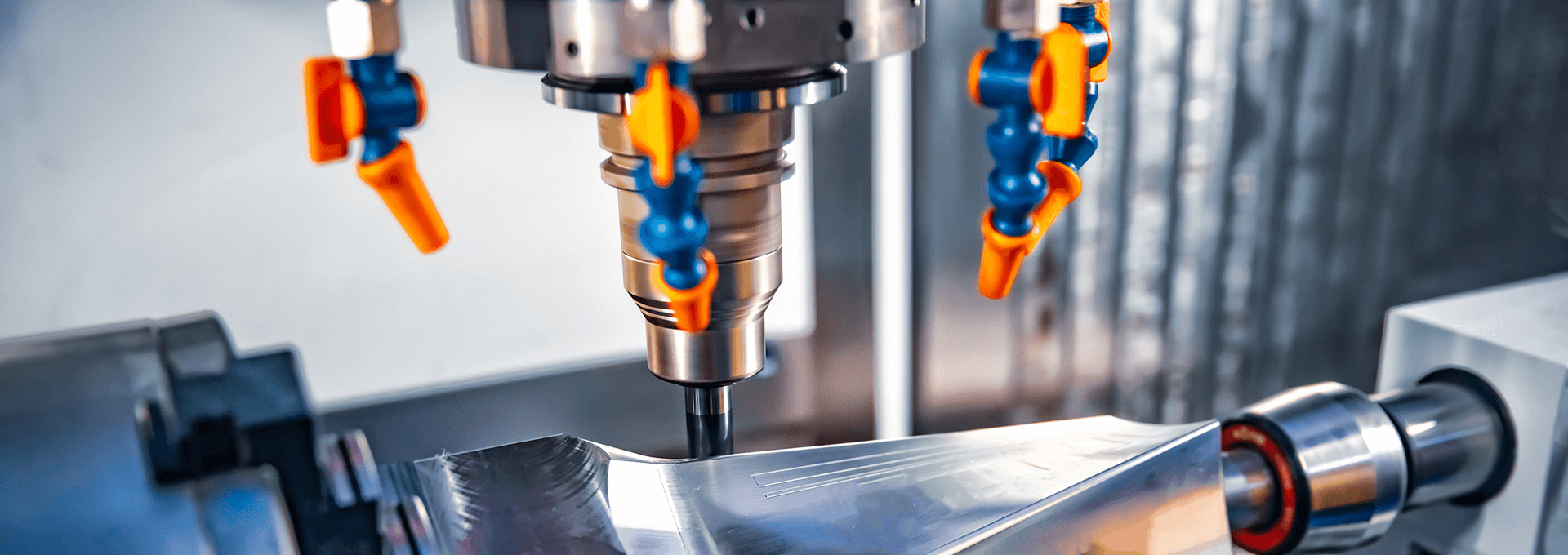

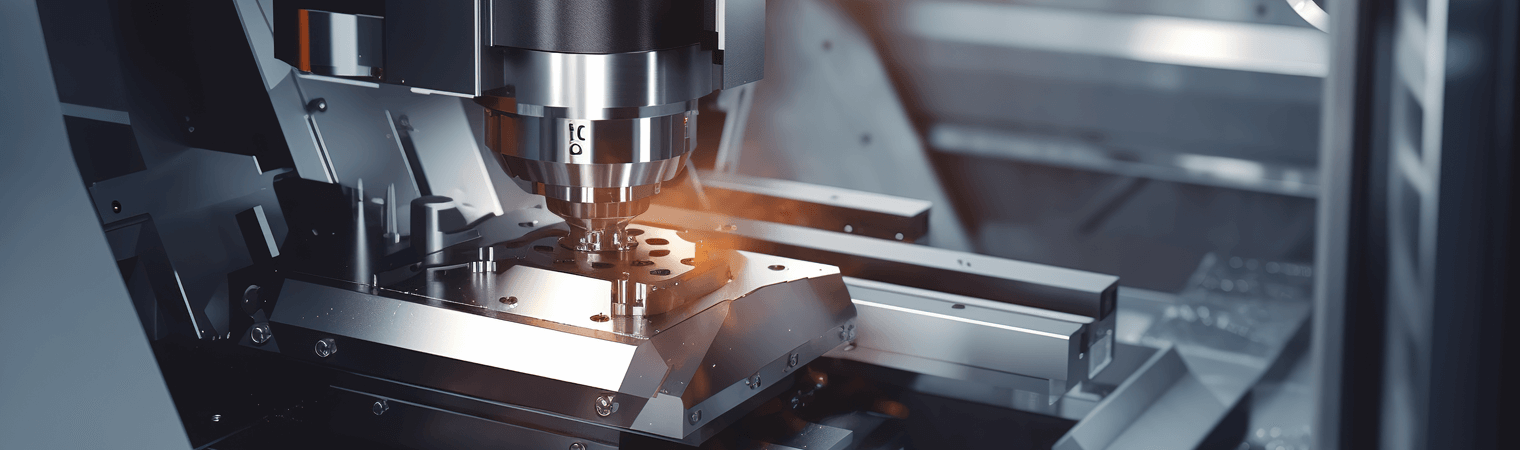

Why Race Mold

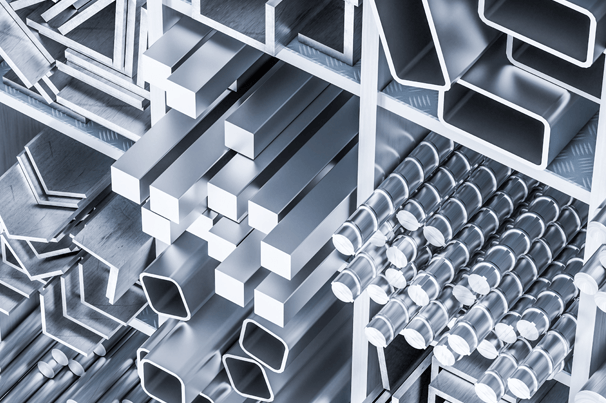

Race Mold is committed to delivering exceptional quality, reliable service, and innovative solutions tailored to your needs. With our extensive experience and dedication to excellence, we ensure a seamless partnership that drives your success.