Produce the finest Molds & Dies in the world.

Our flexibility with today's technologies, knowledge and experience with tooling.

Our Solutions

Plastic Injection Mold

We could make a various range of plastic injection mold for all over the world. Including appliance product, fitness components, automotive parts and various electric/electronic parts in different system like DME, Hasco and so on. With good communication with customers we did a lot of good jobs for our customers.

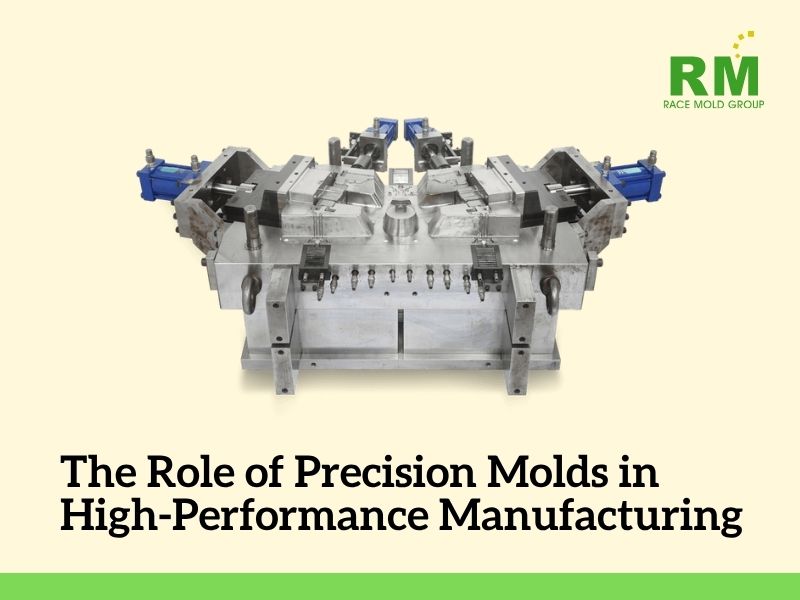

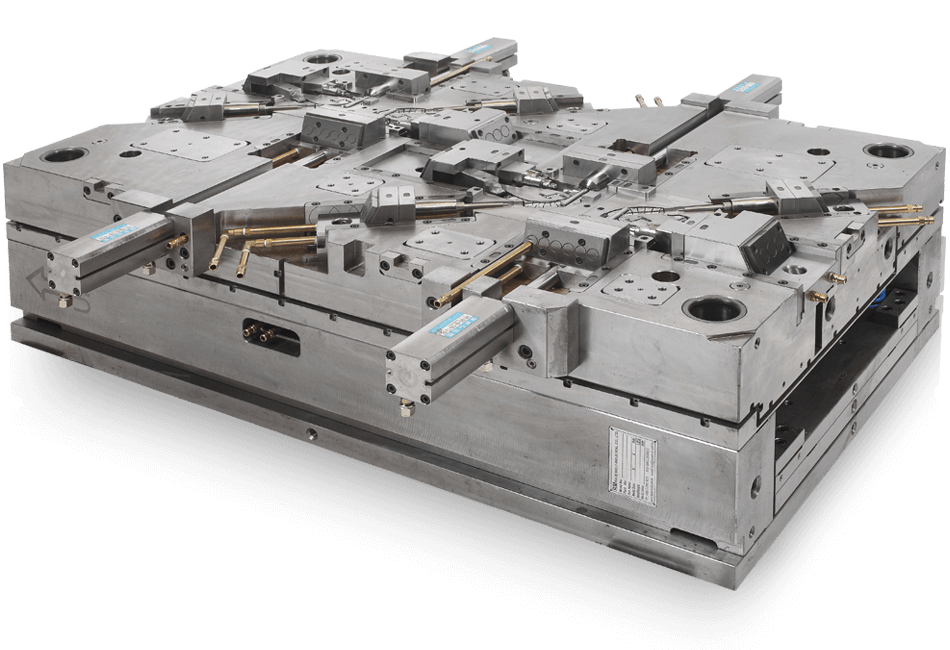

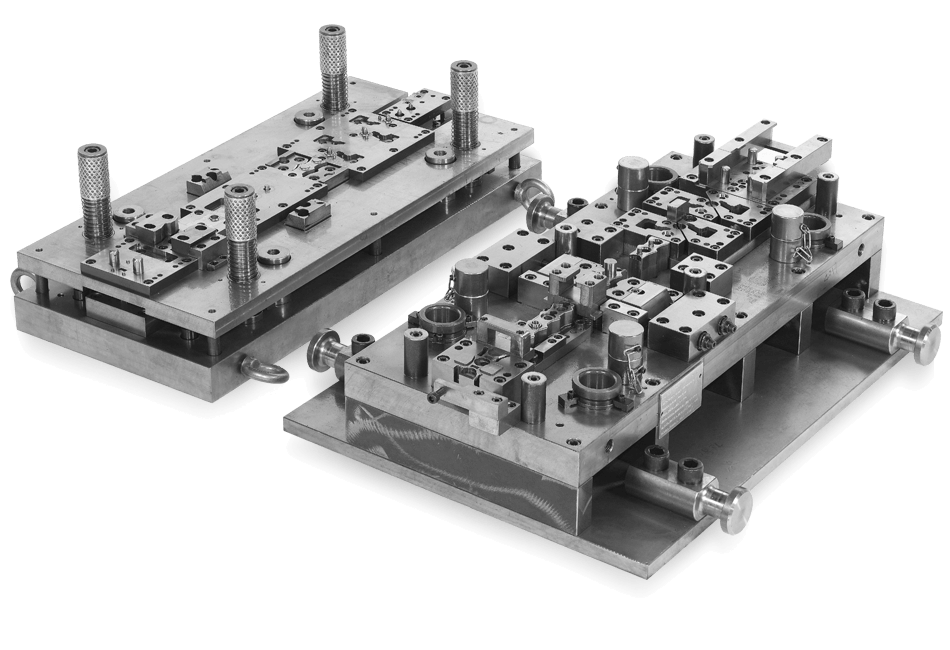

Metal Stamping Die

Race Mold designs & manufactures metal stamping tools. Our experience includes work in the automotive, motorbike, ATV, lawn & garden, cookware & appliance industries. We specialize in progressive & automated transfer dies & stock thickness to 5mm.

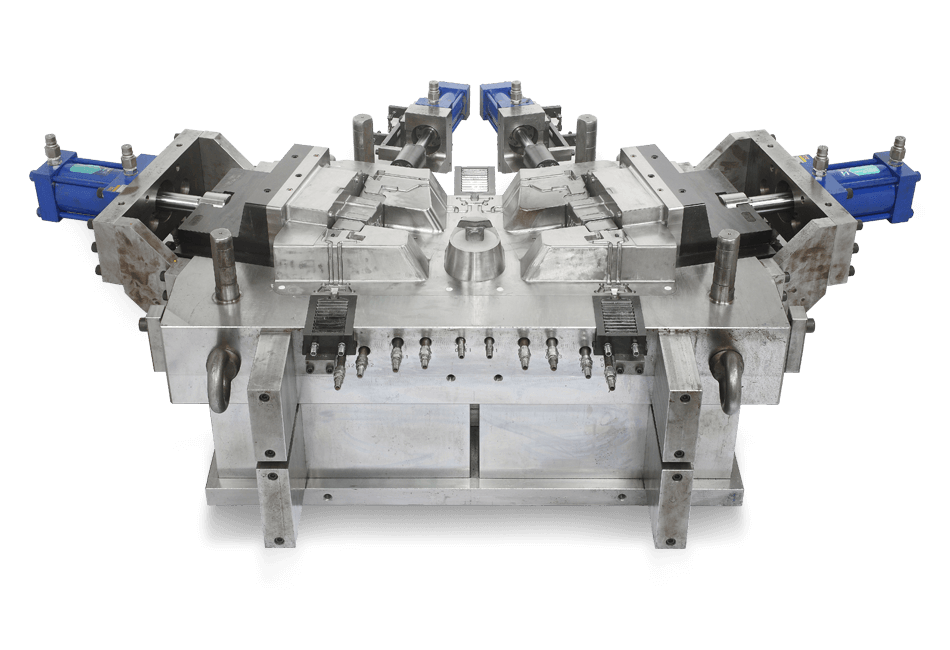

Die Casting Mold & Trim Die

Race Mold has successfully expanded die casting tooling to the worldwide market by forming partnerships with many automotive foundries. As a reliable mold specialist in die casting mold industrial, we continue to improve our procedure & quality control system. We are’ always ‘’Racing’’ as to keep us on the top of Leading Edge Company. The Max. DCM press is 2700 ton Itapresse, die weight up to 25 tons. Pilot run & secondary operation is available by request.