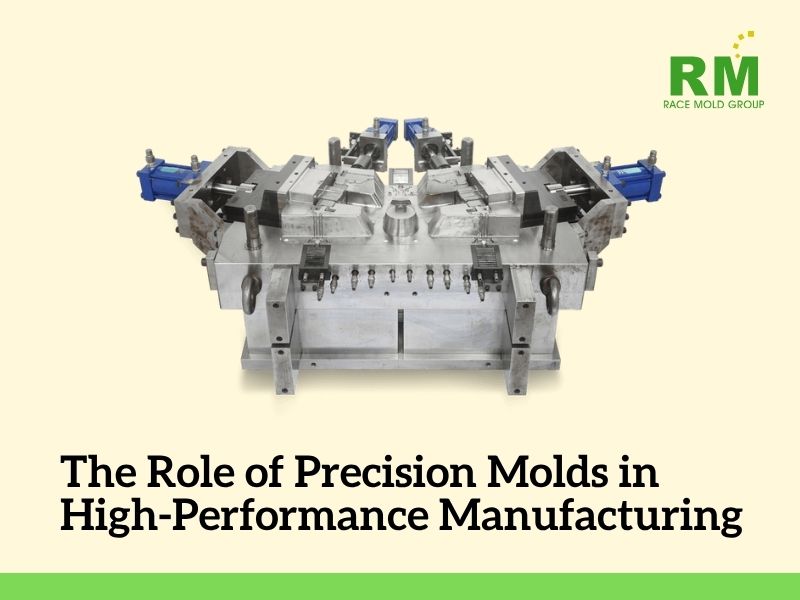

In high-performance manufacturing environments, where speed, accuracy, and consistency are essential, precision molds play a pivotal role. These molds enable manufacturers to achieve exacting standards across industries like automotive, electronics, medical, and aerospace.

At RACE MOLD, we understand the critical role that precision tooling plays in ensuring product success. This article explores how precision molds support high-performance manufacturing—and why choosing the right mold partner makes all the difference.

What Is a Precision Mold?

A precision mold is a highly engineered tool designed to produce parts with extremely tight dimensional tolerances, often within ±0.01 mm or less. Unlike conventional molds, which may prioritize output volume over part accuracy, precision molds are optimized for:

-

Exact repeatability over large production runs

-

Superior surface finish and dimensional stability

-

Reduced part variation for high-performance applications

Precision molds are commonly used in applications where product reliability and micro-level accuracy are non-negotiable.

Key Characteristics of Precision Molds

To qualify as a precision mold, several factors must be met during design, machining, and quality control stages:

-

Tight Tolerance Control

Every cavity and core must be machined with exceptional accuracy, often requiring ultra-precise CNC, EDM, or grinding technologies.

-

Stable Materials

Precision molds are typically made from high-grade tool steel, capable of maintaining accuracy under thermal expansion, pressure, and extended production cycles.

-

Advanced Cooling and Venting

Uniform temperature control is essential to avoid shrinkage, warping, or deformation of parts during the molding process.

-

High-Precision Mold Base and Components

Components such as ejector pins, guide pillars, and sliders must be produced and assembled with tight alignment tolerances.

-

Rigorous Quality Inspection

Precision molds undergo full dimensional checks using CMM (Coordinate Measuring Machines), 3D scanning, and trial sampling to validate every detail before mass production.

How Precision Molds Differ from Standard Molds

| Feature |

Precision Mold |

Standard Mold |

| Tolerance Accuracy |

±0.01 mm or tighter |

±0.05–0.1 mm |

| Suitable Applications |

Medical, electronics, optics |

Consumer goods, packaging |

| Tooling Complexity |

High (multi-cavity, insert, etc.) |

Moderate |

| Mold Life Expectancy |

Long (with hardened materials) |

Medium |

| Machining Requirement |

Ultra-precise CNC and EDM |

Standard machining |

Where Are Precision Molds Used?

Precision molds are essential in industries where even the smallest variation in product geometry can lead to failure or safety issues. Common application sectors include:

-

Automotive – Connectors, gear housings, interior components

-

Medical – Syringe parts, diagnostic device housings, fluid connectors

-

Electronics – Sensor casings, circuit board brackets, mobile components

-

Aerospace – Structural plastic fittings, lightweight high-tolerance parts

-

Optics – Lens holders, reflective modules, light guides

Why Precision Molds Matter

In high-value industries, the smallest errors can result in significant losses—whether through product rejection, rework costs, or compromised safety. Precision molds ensure:

-

Consistent part quality across thousands or millions of cycles

-

Improved assembly performance with tight-fit tolerances

-

Lower production waste due to reduced variation

-

Regulatory compliance, especially in sectors like healthcare and aviation

Choosing the right mold maker is therefore critical to ensuring manufacturing success.

RACE MOLD: Your Partner in Precision Mold Manufacturing

At RACE MOLD, we provide end-to-end services for precision mold development, from concept design and mold flow analysis to high-accuracy machining and full-scale quality inspection. Our engineering team brings decades of experience and a commitment to precision in every detail.

To meet the demanding standards of modern industries, RACE MOLD is equipped with advanced facilities and a comprehensive workflow, including:

-

High-speed CNC machining centers, wire-cut EDM, and double-head EDM for ultra-fine detail processing

-

Mold flow simulation and CAD/CAM software to optimize design before manufacturing

-

In-house CMM (Coordinate Measuring Machine) for precision verification and dimensional control

-

Large-scale mold-making capability supporting molds up to 20 tons and press sizes up to 3,000 tons

-

Gas-assisted injection, insert molding, overmolding, and hot runner systems to handle complex product structures

Our mold production adheres to international standards such as DME, Hasco, and custom specifications upon request. Every project is carefully managed by our professional team—from quotation and project review to DFM (Design for Manufacturability), mold trials, and shipping—ensuring quality, speed, and transparency at every stage.

Whether you require tight-tolerance plastic parts, multi-cavity molds, or precision tools for automotive, medical, or electronics applications, RACE MOLD is ready to support your success with precision-engineered solutions and responsive service.

Conclusion

Precision molds are more than just tools—they are the foundation of high-performance manufacturing, enabling accuracy, repeatability, and long-term efficiency. Whether you're producing safety-critical components or complex multi-cavity parts, investing in precision tooling ensures your operation stays ahead of the curve.

If you're looking for a trusted precision mold partner, contact RACE MOLD today. Let us help you achieve manufacturing excellence through precision-engineered solutions.